STALG (molding and production of technical rubber articles) was founded in 1967 by Vincenzo Pallotta, with the help of his son Roberto, as a small

artisanal business. Since 1994, with the support of his grandsons Alessandro and Fabrizio become a well-known and established

technological company in Central and Southern Italy, as well as throughout Italy and Europe. For over 50 years, we have been manufacturing rubber

products for the electronics, mechanical, pharmaceutical, civil, and military sectors.

Since 2022, STALG apply the INDUSTRY 4.0 system.

In its own mixing department, it produces over 200 types of natural rubbers (NR), synthetic rubbers (SBR), Neoprene (CR) etc .. using raw materials that offer the most extensive guarantees of quality and environmental impact.

The high technology achieved by STALG allows:

- print silicone articles (both compression and injection) in VITON, polyurethane and FVMQ;

- making gaskets, parts for individual protection devices (civil and military), trolley wheels, details with rubber-metal connections, anti-vibration mounts, medical items, products intended for the food industry;

- produce drawn drawn on drawings; make slabs / mats of various types and sizes

The production lines of STALG provide for the following divisions:

Currently the compound room, to continuously feed the production departments, has a closed mixer and three open.

The mixing division is supported by an internal laboratory for the control and chemical-physical testing of the compounds.

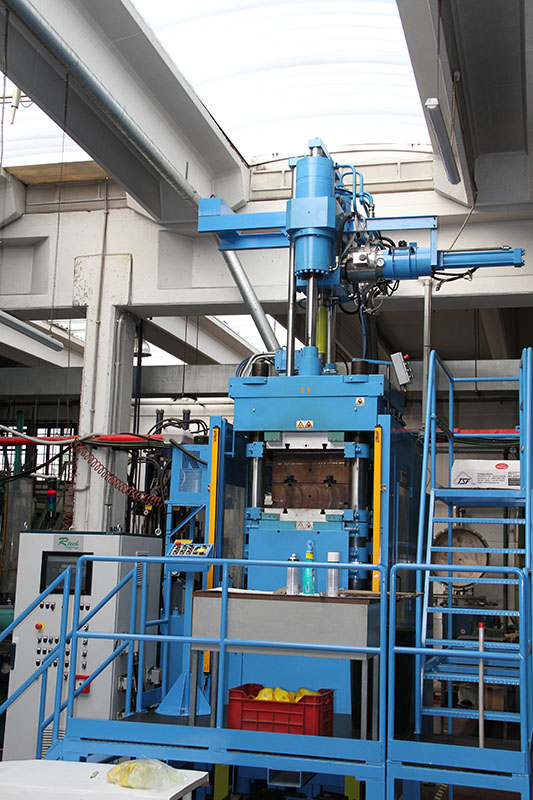

In the area dedicated to molding are used: compression, injection and columnless presses

The presses can print articles of various types and shapes but with the maximum size limit of mm. 1000 x 1200.

The drawing department, supported by an autoclave vulcanization system (horizontal and / or vertical) with steam or hot air, is able to realize any type of figure.

The sheets and the rubber mats, made by STALG, are born to meet the needs of industrial and civil markets.

Depending on the explicit and implicit needs of the various customers, STALG is able to suggest the most suitable elastomer for use; the choice, suggested, will take into account factors such as:

- place where the product (usually in the form of a floor) will be applied;

- chemical, physical, mechanical and atmospheric agents to which it will be subjected;

- anti-slip properties;

- fireproof properties;

- anti-allergy properties;

- characteristics related to cleaning and maintenance;

- aesthetic characteristics.

STALG is always willing to collaborate in solving special cases and responding to specific needs highlighted on technical specifications.

Macchinario per lo stampaggio a caldo

Macchinario per lo stampaggio a caldo

Macchinario per lo stampaggio a caldo

Reparto Mescole

STALG DI V. PALLOTTA by Roberto Pallotta

Via di Cervara 186 - 00155 Rome

Telephone +39 062294435 r.a.

Fax: +39 062294436

e-mail: info@stalg.com

VAT Number : 12109671003 - Fiscal Code : PLLRRT46P04H501F

General Manager: Roberto Pallotta

Sales Manager: Alessandro Pallotta

Quality Manager: Fabrizio Pallotta

Administration: Lina Blasi